A concept case design for the Onion Omega Expansion Dock.

The plan now is to 3D print this and refine it to accept expansion modules.

A concept case design for the Onion Omega Expansion Dock.

The plan now is to 3D print this and refine it to accept expansion modules.

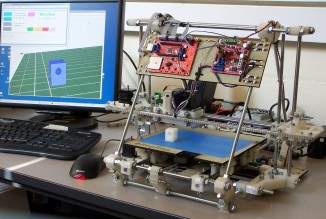

So after getting the heatbed installed, wired in and then upgrading the firmware, here is an image of the premier heatbed print.

Time to get down and dirty with the Marlin firmware for the RAMPS 1.4.

Luckily bq have made the Hephestos firmware avaliable as a well documented github repository, just what you need to get started.

When it comes to 3D printing, you have a choice of the normal filaments: PLA or ABS. Basically ou can print PLA filaments (not ABS) onto rough surfaces, in my case a glass plate with some hair spray (because i’m worth it,) or you can print both onto heated surfaces. This heated surface or heatbed (not the kind you sleep in) allows the filament to stick to the printing surface at the start of printing and also stops the filaments from cooling to quickly and warping. Exact temperaturs are usually given by the filament manufacturer.

Guess it’s already time to upgrade to a heated bed (good thing i already ordered the parts)

Having browsed the endless pages and sourcing various parts from the vast resource that is the interwebs the decision was made…

Given the current price for a decent sized consumer 3D printer and having the urge to build anything, stumbling across the RepRap.org project (albeit a bit too late) was bound to lead to a 3D Printer project.

So having looked in awe at the latest consumer 3D printers and dreaming of that first extrusion, the time has finally come!

A project all about building and modifying a RepRap 3D Printer.